Sodiceram and the New Era of Ceramic Innovation

Sodiceram is transforming the ceramics landscape in a meaningful way. Picture a material that blends modern innovation with environmental responsibility, producing items that are visually refined and eco-conscious at the same time. This advanced approach relies on sodium-based compounds, clearly distinguishing it from traditional ceramic materials. Built on advanced scientific research, Sodiceram unlocks a wide range of opportunities for producers and end users alike.

As more industries move toward sustainable alternatives, Sodiceram is setting the pace. It goes beyond long-lasting products and focuses on shaping a cleaner future while enhancing technical performance across multiple uses. This evolving technology invites us to rethink ceramics and explore the long-term potential it brings.

Benefits of Using Sodiceram-Based Compounds in Ceramics

Sodium-based compounds provide clear benefits when used in ceramic production. They enhance melting behavior and support more controlled, efficient firing cycles. As a result, manufacturers can reduce energy consumption during production.

These compounds also strengthen ceramic structures. When sodium is added to ceramic formulas, it supports a dense and resilient composition that performs well under stress.

Another key benefit is reduced thermal expansion. Ceramics produced with sodium-based materials are more resistant to cracking caused by temperature changes, making them suitable for diverse environments.

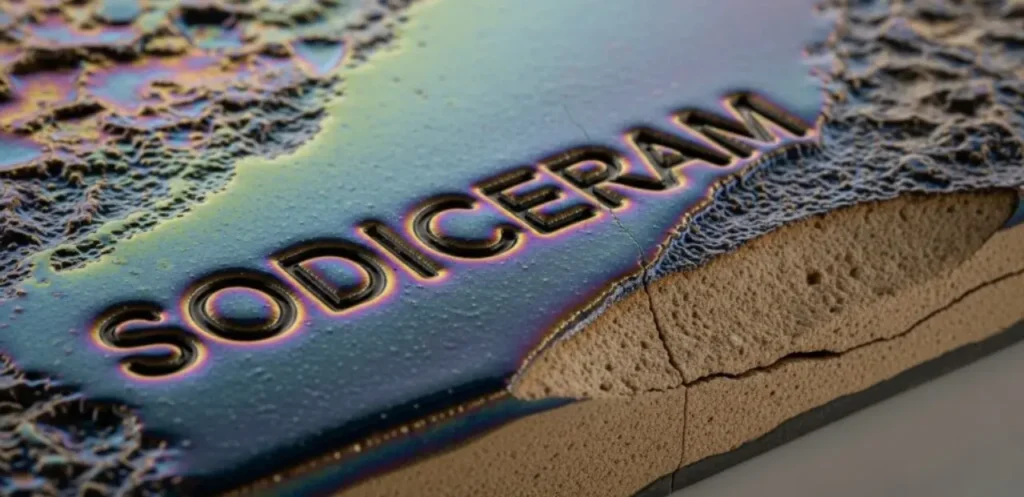

In addition, sodium compounds improve glaze bonding, leading to smooth, durable, and visually attractive surfaces. Incorporating sodium into ceramics expands creative and technical possibilities while delivering noticeable performance improvements.

Ceramics Produced with Sodiceram

Sodiceram supports the creation of many ceramic types. This flexibility comes from the distinctive characteristics of sodium-based compounds.

Porcelain is one prominent example, valued for its strength and semi-translucent quality. Sodium enhances its toughness while preserving its refined visual appeal.

Stoneware is another important category, recognized for durability and resistance to thermal stress. Sodiceram contributes to a refined surface texture, making stoneware suitable for functional items and artistic pieces. Its ability to support rich colors also attracts creative professionals.

Advanced high-performance ceramics are also developed using sodium-enhanced formulas. These materials are vital in demanding fields such as aerospace and electronics, where accuracy and reliability are essential.

Sodiceram Applications Across Industries

Sodiceram is applied in many sectors, highlighting its adaptability. In construction, it is commonly used for tiles and bricks, offering both structural reliability and visual quality.

The automotive sector benefits from Sodiceram’s thermal stability. Its resistance to heat makes it suitable for components exposed to high operating temperatures.

In electronics, Sodiceram is used for insulating materials and substrates due to its strong electrical resistance. This improves device longevity while maintaining consistent performance.

Artists also embrace Sodiceram for decorative objects and sculptures. The material allows for bold colors and detailed forms made possible by sodium-based compounds.

Healthcare industries utilize this ceramic innovation because of its compatibility with medical and dental applications. These wide-ranging uses emphasize Sodiceram’s importance in modern manufacturing environments.

Strengths and Drawbacks of Sodiceram

Sodiceram offers multiple strengths that appeal to ceramic manufacturers. Its sodium-based composition improves durability and supports resistance to wear, making it suitable for demanding applications.

It also enhances thermal behavior. Ceramics produced with Sodiceram often provide improved insulation, which is useful in heating-related uses.

However, there are challenges. Manufacturing can be more intricate than standard ceramics because sodium compounds require careful processing. This added complexity may increase production expenses.

Although its advantages are notable, performance can vary depending on formulation and conditions. A clear understanding of these factors is essential for industries planning to adopt Sodiceram effectively.

Future Developments and Possibilities of Sodiceram

The outlook for Sodiceram is promising. Ongoing research is identifying new sodium-based materials that further improve ceramic performance.

Advancements in material science may result in ceramics that are both lightweight and strong, expanding their use across multiple sectors.

Sodiceram’s adaptability is also gaining attention. Its role in sustainable construction materials and environmentally friendly products is growing as environmental awareness increases.

Progress in 3D printing technologies could further transform how Sodiceram is used. Custom-designed ceramic components may be produced efficiently, supporting specialized applications.

Cross-industry collaboration may unlock even more innovative uses, ranging from healthcare solutions to advanced electronic systems. As exploration continues, the potential of Sodiceram becomes increasingly clear.

Conclusion: Why Sodiceram Is the Future of Ceramics

Sodiceram is at the forefront of ceramic innovation. This unique material, enriched with sodium-based compounds, offers several advantages that conventional ceramics cannot match. Its versatility enables a wide range of applications in diverse industries, from construction to art.

The advantages of Sodiceram are compelling. It features increased durability, heat resistance, and aesthetics. These properties make it an attractive option for manufacturers seeking high-performance materials.

As technology advances, so does the potential of Sodiceram. Ongoing research could open up new possibilities or further improve existing properties. The future looks bright as more and more industries recognize the value of Sodiceram.

As sustainability in manufacturing becomes increasingly important, Sodiceram offers a more environmentally friendly alternative to conventional ceramics. This aspect is in line with global trends aimed at reducing the ecological footprint while maintaining quality.

In a constantly changing world where innovation is key to competitiveness, the use of materials like Sodiceram could pave the way for advancements in ceramic design and functionality.

The journey has just begun; this is just the beginning of a potentially groundbreaking chapter in the history of ceramics.